What is Artificial Intelligence Visual Inspection for Defect Detection? : A Deep Dive

Artificial Intelligence (AI) Visual Inspection for defect detection is a modern solution that combines computer vision and machine learning to automatically spot flaws in products during manufacturing. Instead of relying solely on human inspectors, AI-powered systems analyze images or videos from production lines in real time, identifying scratches, cracks, misalignments, or other defects with high accuracy.

This technology matters more than ever because industries today face rising pressure to deliver zero-defect products, meet stringent compliance standards, and maintain customer trust. Traditional manual inspection can be slow, inconsistent, and costly. In contrast, AI-driven inspection scales effortlessly, working 24/7 with consistent precision.

With the acceleration of Industry 4.0, automation, and smart factories, AI Visual Inspection has become a critical enabler for boosting efficiency, reducing waste, and improving overall product quality. It is transforming manufacturing from reactive quality checks to proactive, predictive quality assurance.

This blog offers insights on why AI visual inspection is a game changer, real-world implementations, its benefits, challenges, and emerging trends.

Here are the top trends in AI visual inspection in 2025.

Combines visual data with sensor inputs like thermal or X-ray imaging for comprehensive defect detection, uncovering flaws invisible to traditional vision systems.

Brings transparency by showing why a defect was flagged, helping operators trust and validate AI decisions while easing regulatory compliance.

Uses historical inspection data to predict when defects are likely, allowing proactive adjustments in processes before quality issues arise.

Generates artificial defect images to train AI, reducing dependency on rare real-world defect samples and accelerating model development.

Integrates AI inspection with IoT-enabled machines to monitor energy use, reduce waste, and support sustainable manufacturing goals in line with Industry 4.0.

Artificial Intelligence Visual Inspection uses artificial intelligence, particularly computer vision, to automatically examine products or components for defects, quality issues, or inconsistencies. It enhances accuracy, speeds up inspection processes, and reduces human error, making it widely used in manufacturing, electronics, and automotive industries for quality control.

AI Visual Inspection is revolutionizing manufacturing by bringing unmatched precision, consistency, and speed to quality control. Traditional manual inspections often struggle with fatigue, inconsistency, and missed defects, but AI overcomes these limitations through advanced computer vision and machine learning.

It can reduce defects by up to 50%, and deliver inspection cycles 30–50% faster, boosting production throughput by about 25%. This improvement means fewer errors, faster time-to-market, and significant cost reductions.

By detecting issues early, manufacturers can minimize scrap, cut warranty costs, and strengthen customer trust. As Industry 4.0 accelerates, AI Visual Inspection has emerged as a critical driver of operational excellence, ensuring manufacturers deliver reliable, defect-free products at scale.

Deep learning technology is becoming more and more popular for use in various industries. Its primary benefit is allowing machines to learn by example rather than explicitly program. Doing this makes it a powerful tool for tasks that are difficult to automate, such as visual inspection.

The basic principle of deep learning is to teach a machine to recognize specific patterns by providing a neural network with labeled examples. Once the device has learned those patterns, it can apply them to new data to identify the defects.

Integrating deep learning algorithms with automated visual inspection technology allows discriminating components, abnormalities, and characters, simulating a human visual examination while running a computerized system.

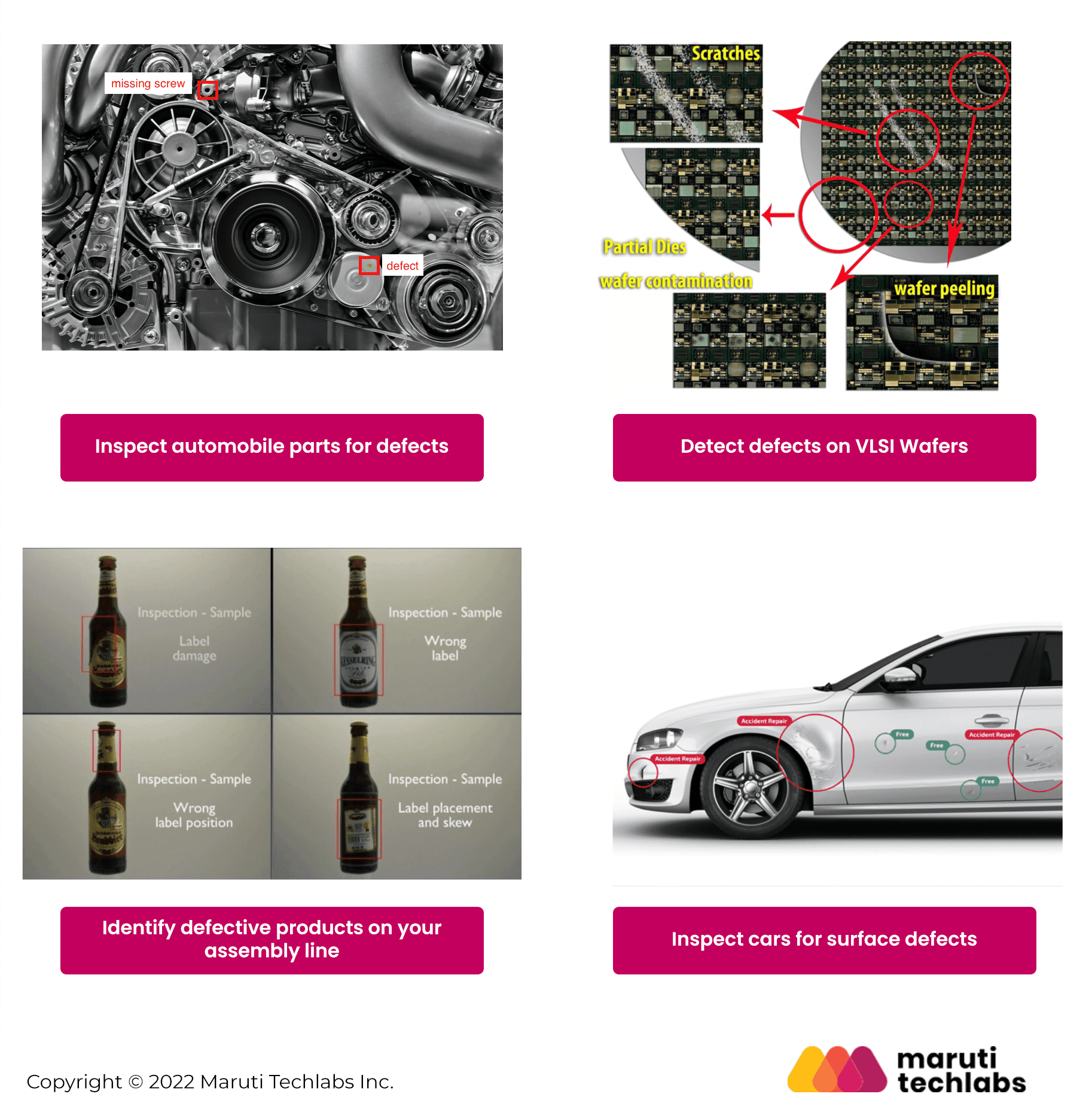

Ford uses AI-powered vision systems like AiTriz and MAIVS to detect minute misalignments and verify correct parts. Deployed across hundreds of assembly stations, these systems have drastically reduced recalls and costly rework, ensuring higher accuracy and consistency in vehicle production.

Chinese manufacturer DeepVision leverages AI to boost product qualification rates to 97%, reducing dependency on manual inspectors. This has significantly cut defects, improved production efficiency, and enabled scalable, real-time quality assurance in high-volume manufacturing environments.

Siemens integrates AI visual inspection in PCB assembly lines to detect soldering defects, cracks, and missing components. These systems reduce inspection time, improve precision in identifying micro-defects, and maintain consistently high output quality across global facilities.

Samsung deploys AI-driven visual inspection to monitor wafer production for micro-level defects invisible to human eyes. This has reduced scrap rates, improved yields, and strengthened the company’s ability to deliver defect-free chips in a highly competitive semiconductor market.

Visual inspection is one of the most commonly used approaches in the production process. It entails visually inspecting the components of an assembly line to detect and repair problems.

However, AI-based visual inspection is frequently described as some form of optical inspection technique based on deep learning and computer vision. It is the process of monitoring and inspecting a manufacturing or service operation to ensure that products meet predetermined specifications.

A computer is used to capture, record, and store images as well as objects. Thus, it saves time and also increases efficiency. For example, if an inspector inspects an assembly line, it may take him/her a couple of hours to finish the inspection process, whereas AI-powered software will scan the assembly line within a few minutes.

Since the advent of industry 4.0 tools, manufacturers can leverage cloud computing capabilities with AI. Here, a camera performs a thorough equipment scan and shares the image on the cloud. A machine learning algorithm analyzes the image for defect detection and identifies any potential defects and nonconformities.

A huge amount of data and images are fed into the system to help reveal even the slightest abnormalities with product quality to enhance defect detection accuracy, eliminating the possibility of human error. The algorithms also contribute largely to reducing the average time taken for thorough inspection compared to human inspection.

Automated visual inspection is widely used in manufacturing to assess the quality or defects. It can help prevent potential negative impacts, such as those that may occur when an organization meets specific compliance requirements. However, you can also use it in non-production environments to determine whether the features indicative of a “target” are present or not.

There are many industry domains where automated visual assessment is required as the high priority activity, due to the potential errors that may arise via manual inspection, such as loss of expensive equipment, chances of injury, rework, or loss of a customer.

The high-priority business domains where automated visual inspection is prioritized include airport screening, the food industry, pharmaceutical, and nuclear weapons manufacturing.

Many companies rely on manual testing as their only quality control measure, but this approach has limitations. Let’s explore some of these limitations:

1. Occasionally Hazardous

Not every time the defect detection entity is safe to inspect. When assessing elements like baggage screening or aircraft maintenance, there are multiple risks involved to inspect such entities under normal conditions.

2. Time Consuming

In property and casualty businesses, studying and assessing the damage to a building or automobile usually takes time. Hence, the inspection and claim settlement process is quite lengthy. Because most of these activities or scenarios are done repeatedly, manual testing takes considerable time.

In such cases, computer vision can significantly speed up the process, minimize mistakes and prevent fraud. Moreover, you can use satellite imagery, drones, and big data to do these computer-assisted inspections.

A typical machine learning application analyzes behavioral data such as facial expressions or voice tone during underwriting. For example, in the case of health insurance, it is projected that behavior monitoring will provide over 40% of risk information.

Additional Read – 9 Real-World Problems Solved by Machine Learning

However, behavioral data is also essential in non-life insurance. For instance, identifying particular trends in how a person runs a machine may suggest process problems resulting in insurance claims.

3. Ineffective

Manual inspection is prone to making two forms of mistake, either failing to detect the error or identifying the defect which doesn’t exist. This ineffective visual detection can lead to ineffective estimations and a waste of employee efforts.

4. Human Vision is Unreliable.

Optical illusions are an example of how untrustworthy the human eye can be. Moreover, when comparing two similar objects with small dimensions, there are chances that the human eye will fail to recognize the slight difference in measurements. It isn’t to say that manual examination is useless; it indicates that relying solely on it isn’t a good idea.

5. Subjective to Inspector

The manual testing procedure is inconsistent since each individual’s testing methods, and tactics vary. Because this yields ranged results on the same test, variance in the test method is unavoidable.

6. Impractical Performance Testing

Performance testing of any client-server application necessitates the use of humans and computers. Client programs must be installed on several PCs and tested by a single person to determine the overall performance of the software, which is a time-consuming and challenging job.

7. Cost of Labor

As individuals on a large scale cannot handle quality inspection, companies tend to hire multiple skilled trainers, and hence, the manual examination remains a costly endeavor. According to Glassdoor, manual inspection operators may earn anywhere between $50,000 and $60,000 per year.

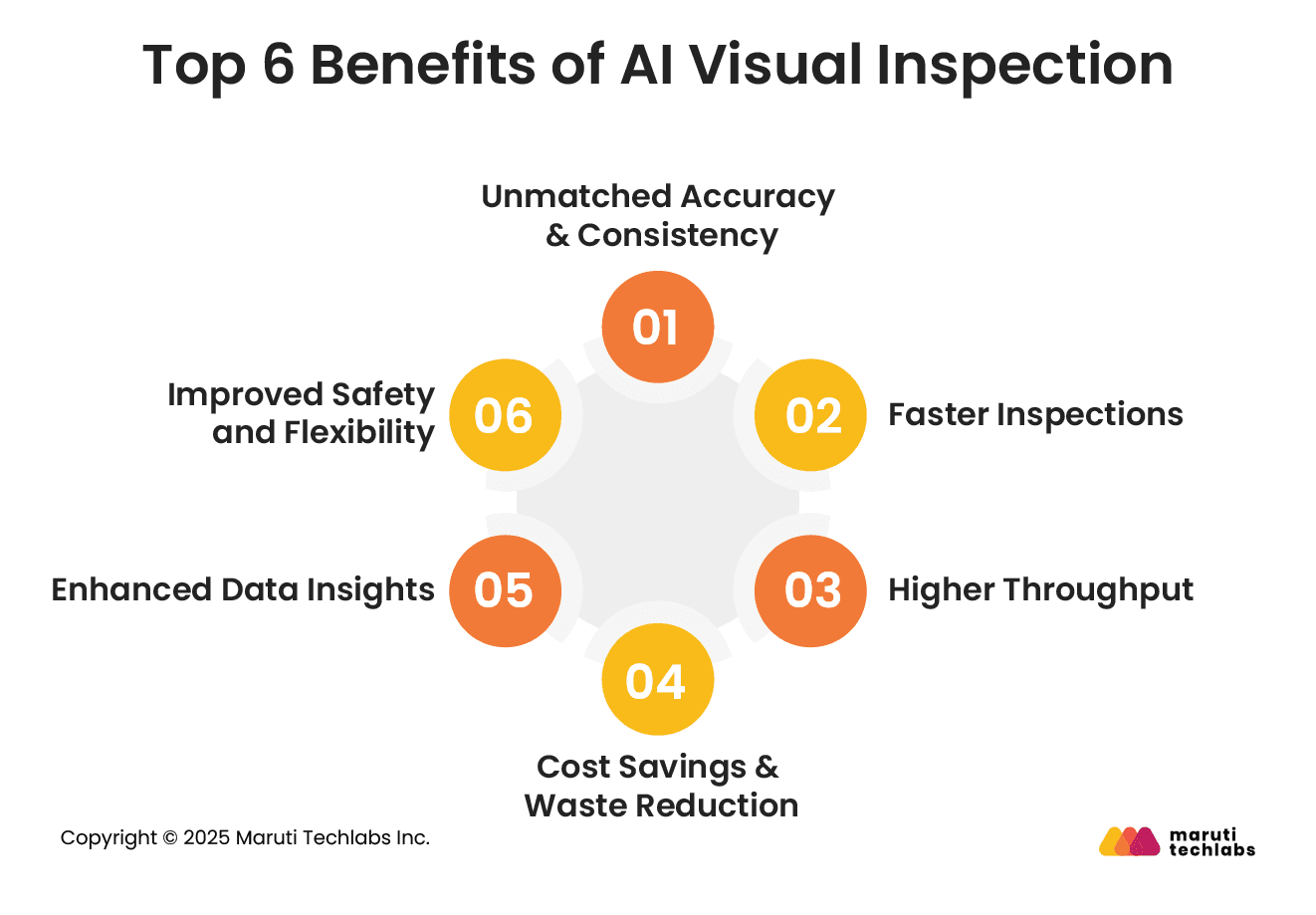

Let’s observe the top 6 benefits of of visual inspections using AI.

AI detects minute defects with accuracy levels up to 96–99%, outperforming human inspectors. It ensures consistent quality across production shifts, eliminates fatigue-related errors, and builds customer trust through defect-free, reliable products.

AI-powered systems analyze images in real time, reducing inspection cycles by 30–50%. This speed enables manufacturers to meet growing market demand without compromising quality, accelerating time-to-market for products.

Automated inspection allows factories to scale operations without adding inspectors. By processing more units per hour with precision, AI increases throughput by up to 25%, enhancing manufacturing efficiency.

By catching defects early, AI reduces rework, warranty claims, and scrap rates. This lowers operating costs while minimizing material waste, directly improving profitability and sustainability.

AI systems generate detailed defect data, helping manufacturers identify root causes, improve processes, and predict failures. These insights foster continuous improvement and stronger quality management strategies.

AI inspection can operate in hazardous or sterile environments, reducing risks to human workers. Its flexibility allows easy adaptation to new products or lines, ensuring future-ready manufacturing.

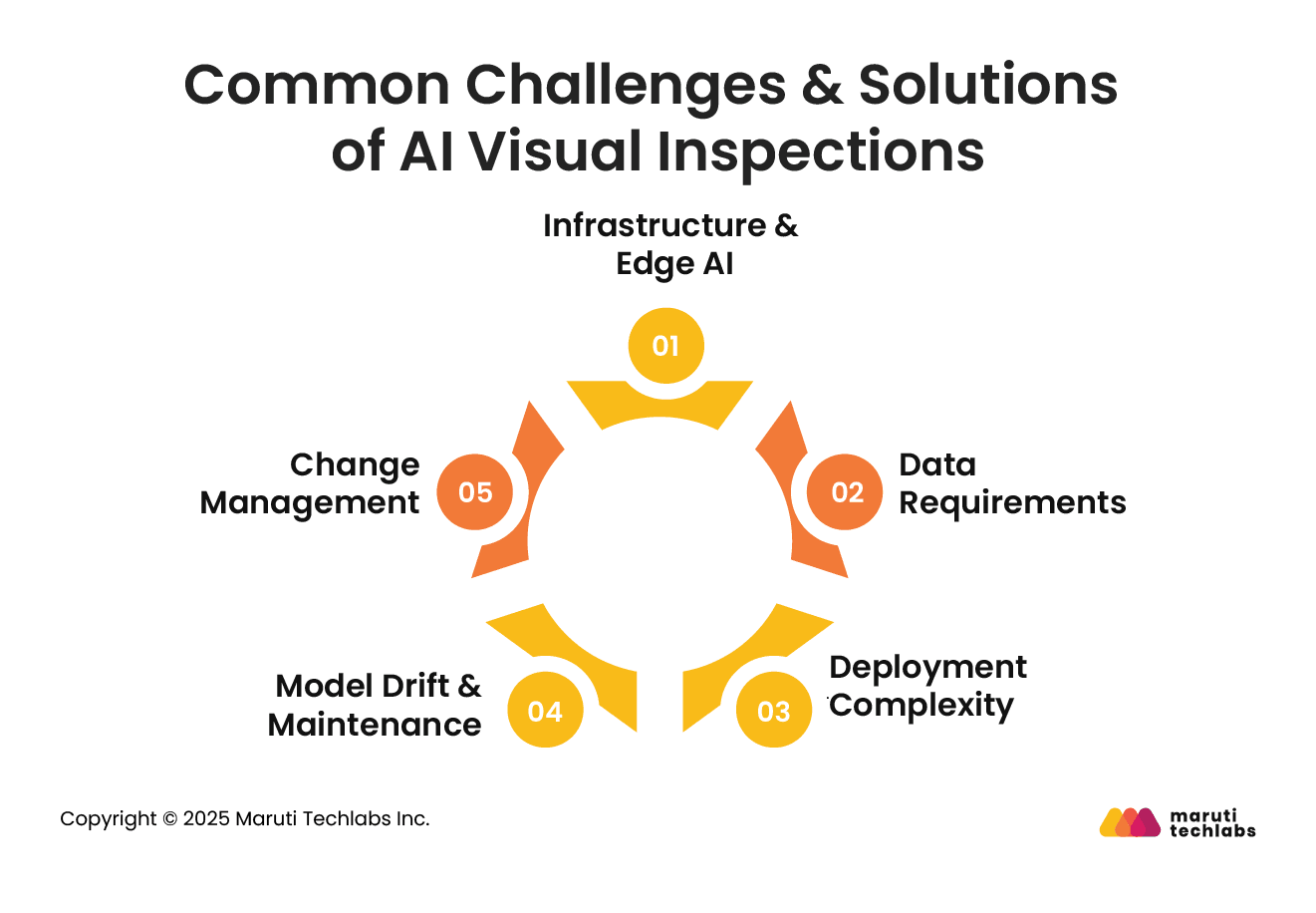

Here is the list of challenges and solutions experienced when implementing visual inspections using AI.

High-resolution cameras and GPUs can be costly.

Solution: leverage Edge AI devices for faster, local processing, reducing latency and reliance on cloud infrastructure while keeping implementation affordable.

AI needs thousands of defect images to train effectively.

Solution: use synthetic data generation to simulate defects and strengthen model performance without waiting for real-world defect accumulation.

Integrating AI into legacy production lines is challenging.

Solution: adopt modular AI systems that work with existing equipment and provide APIs for smoother integration and scalability.

AI models degrade as product designs change.

Solution: implement continuous model retraining with fresh datasets, ensuring inspection accuracy keeps pace with evolving production lines.

Shifting from manual to AI inspection may face workforce resistance.

Solution: invest in training programs to upskill staff, positioning AI as an assistive tool rather than a replacement.

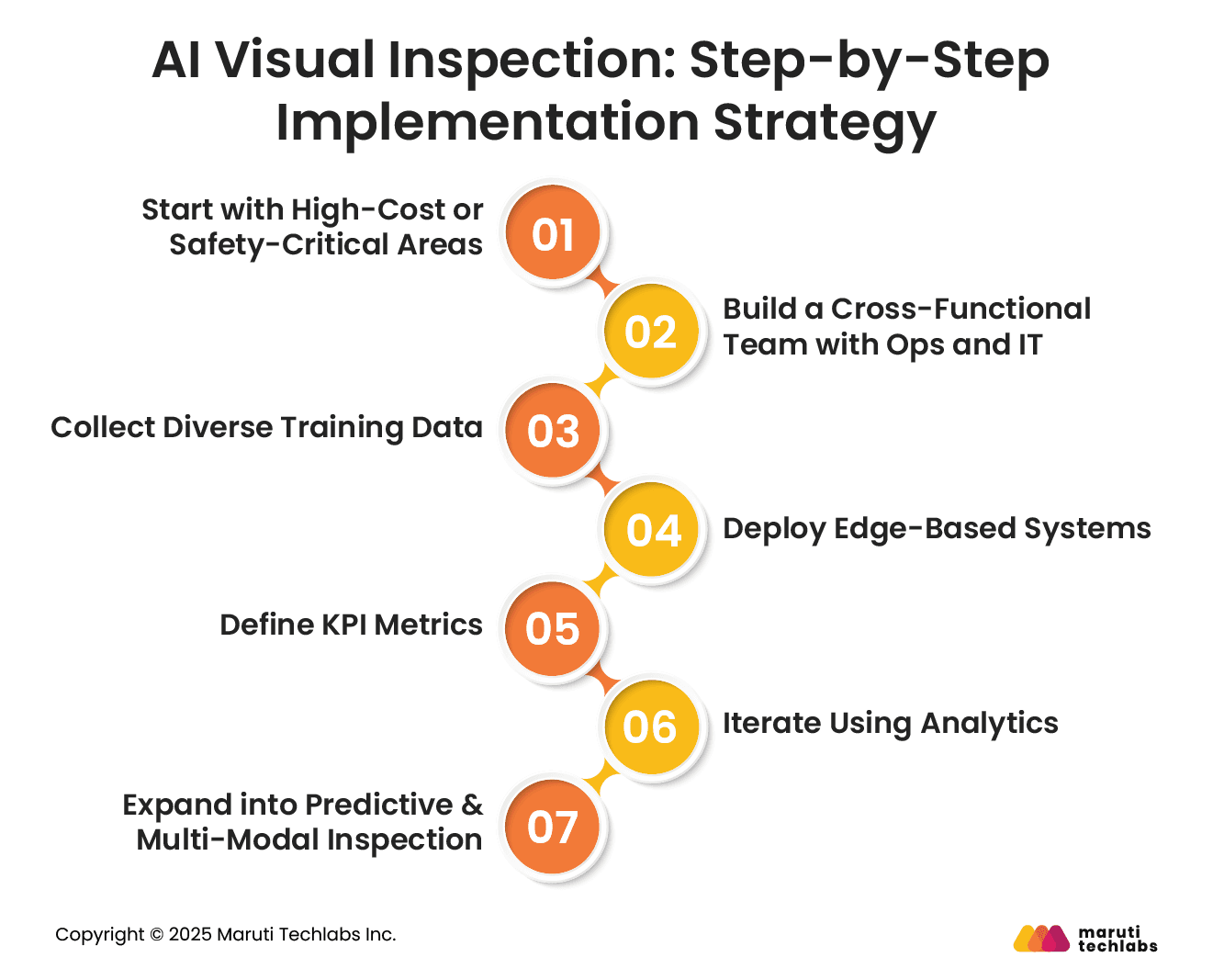

Here’s the perfect stepwise strategy to implement AI visual inspection.

Prioritize AI visual inspection where defects are most expensive or pose safety risks—such as automotive parts, semiconductors, or pharmaceuticals. Early deployment here delivers maximum ROI, builds stakeholder confidence, and creates a strong case for scaling automation across the factory.

Success requires collaboration between operations, quality assurance, IT, and data science teams. This ensures technical feasibility aligns with production realities, avoids silos, and drives faster adoption. A strong cross-functional team enables seamless integration, issue resolution, and alignment with strategic goals.

Robust AI requires large datasets covering multiple defect types, lighting conditions, and product variations. Where real-world defect images are scarce, synthetic data can simulate flaws, boosting training effectiveness and accelerating deployment. This approach strengthens models for reliable inspection under varied conditions.

Implement inspection at the production line edge for real-time defect detection without relying on cloud latency. Edge AI reduces bandwidth costs, increases reliability, and allows immediate corrective action, ensuring production flows smoothly and defects are caught instantly.

Measure system performance with clear KPIs such as detection accuracy, inspection cycle time, throughput increases, and reduced defect rates. These benchmarks track ROI, justify investments, and guide model improvements, ensuring AI systems deliver measurable business and operational value.

Continuous improvement is key. Use AI inspection data to analyze recurring defect patterns, identify root causes, and feed insights back into processes. Iterative updates improve both production quality and model accuracy, ensuring sustained gains over time.

Once stable, extend systems into predictive quality, forecasting potential failures before they occur. Adopt multi-modal inspection by combining visual with thermal, X-ray, or acoustic data for comprehensive detection. This future-proofs inspection and maximizes long-term efficiency gains.

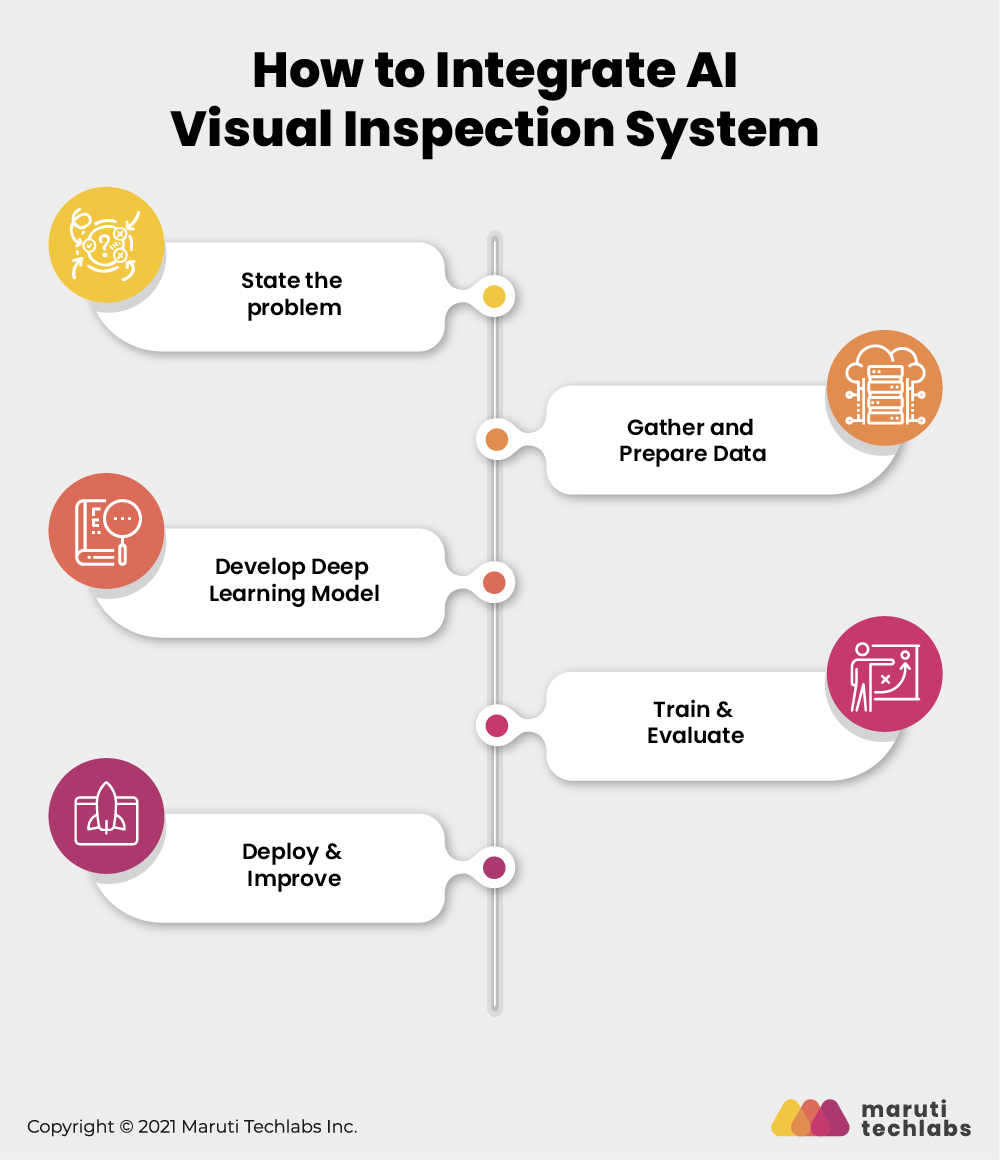

Below are the five steps to follow while integrating an automated visual inspection system:

It is essential to understand that the goal of the inspection is not to find all possible defects but to determine what kind of defects the system should detect. These are the defects that affect quality, safety, and reliability so that the customer can identify and care about them. To help you with the same, here are the essential steps to follow while identifying the actual problem statement for integrating automated inspection in manufacturing:

As an engineer in the data science field, you must prepare and gather the required data sets before deep learning can begin. For manufacturing industries, it’s important to digitize the product supply chain through IoT analytics. For instance, if we are talking about video records, the data preparation can include extracting frames from videos and creating bounding boxes on relevant objects on these frames.

There are many ways to collect the dataset; however, below are some of the standard methods:

After obtaining the data, we make sure it is orderly and ready to be modeled. Any anomalies explicitly related to this are checked for before proceeding.

In this stage, you identify the perfect deep learning model depending on the complexity of your system, budget limitations, and time constraints. Below are some of the common approaches:

This approach is based on feature engineering. You are provided with the set of heuristic rules that experts in the field specifically derived to detect objects in images. This type of model is beneficial when the requirements of defect detection features are in line with the templates provided by the service. Doing this can save time and budget as there is no need to develop the model from scratch.

A pre-trained model is a deep learning model that has previously been constructed and performs tasks similar to those you want to complete. Pre-trained models may not always succeed on all of our tasks, but they offer significant time and cost savings. Using models previously trained to solve large datasets allows us to customize them for our needs.

When developing the custom deep learning model from scratch, a data scientist should consider using many computer vision algorithms, for example, image segmentation, object detection, etc. This method is ideal for complex, secure inspecting systems. The approach may be time and effort-intensive, but the results are worth it.

For instance, consider an automated visual inspection system for assessing the automotive parts that detect scratches on the metal surface. After training the system, it can accurately detect all kinds of dents and scratches. In such cases, you don’t need to develop a completely different model and instead collect the images depicting defective, unacceptable parts.

After developing the visual inspection model for your system, now it’s time to train it. Here, the data scientist has to test and evaluate the performance of your system and its result accuracy. Test dataset may be anything that can support the automated visual inspection system; it may be a set of video records that we are processing.

Once you evaluate your model, it’s time to deploy and inspect it daily. Instead of directly applying your model on a large scale, you can test it on some of your products and identify its accuracy. If it satisfies the requirements you are looking for, you are good to integrate it with your entire system. Also, it is recommended to regulate your model quickly using the new dataset and trends available in the market.

By using Artificial Intelligence to inspect products, you can save time and money by eliminating manual inspections, the need for extra employees, and building a more robust and more accurate inspection process.

Businesses can benefit a great deal by using automated visual inspection. For example, the manufacturing industry can easily automate the detection of incongruities in manufactured objects. This use case also translates well into the insurance sector. And that’s exactly what we at Maruti Techlabs built for one of our clients.

The Challenge

One of our clients from the motor insurance sector was facing the challenge of manually detecting the amount of damage to the cars in accidents. Service inspectors had to assess the vehicle’s condition and make judgments physically.

Not only did this delay approvals for the customers of our client, but it also resulted in erroneous judgments – leading to poor customer service and lost business opportunities. The high workload and turnover rate in the inspection team were not helping the business either.

The Solution

With the help of computer vision and deep learning frameworks, our data engineers built a model to detect the percentage of damage in the vehicles automatically. We trained the model using thousands of images provided by our client. The model assessed the vehicle’s body and automatically detected the extent of the damage. The entire process was reduced from a matter of days to a fraction of seconds with the help of the AI model for visual inspection for defect detection.

We further eased claims processing by building a custom chatbot for customer-facing queries. Instead of reaching out to different customer service reps and facing long wait times, the customer could now simply raise a car insurance claim through the chatbot.

All the customer had to do was input their policy number, raise a claim request, and upload photos of the damaged car through the chatbot. The photos uploaded through the bot would be fed into the machine learning model, which would then process the images and calculate the damages.

The entire workflow resulted in better customer engagement, more productive employees, and, most importantly, better business outcomes for our client.

Over the years, the simple camera clicks we’ve been accustomed to, have resulted in an exponential increase in the volume of digital media. At Maruti Techlabs, we help you utilize this rich data to scale visual technologies to provide accurate detection results. Our team of dedicated AI specialists has years of experience enabling companies to leverage the power of computer vision solutions to improve their business processes.

Get in touch with us to leverage the power of computer vision for your business!

Leverage our AI Readiness Assessment Tool to evaluate your organization's preparedness for adopting AI technologies.

The four types of quality inspection are pre-production inspection, during production inspection, pre-shipment inspection, and container loading inspection. Each ensures product quality at different stages of manufacturing and delivery.

AI testing involves using artificial intelligence to enhance software testing processes. It includes automating test case generation, improving test coverage, detecting bugs, and predicting potential failures, making testing faster, more innovative, and more efficient.

Visual inspection AI costs vary based on complexity and scale, typically ranging from $10,000 to over $100,000 for deployment. Costs include software, hardware (like cameras), integration, and ongoing support or updates.

AI can detect visual defects such as scratches, dents, cracks, discoloration, missing components, surface contamination, deformations, and alignment issues. It uses computer vision and deep learning to identify anomalies in real-time with high accuracy.